How Drainage Composites Have Changed the Landscape

- Home

- Team EJP Blog

- How Drainage Composites Have Changed the Landscape

- Dec 2, 2020 2:08:39 PM

- Everett J. Prescott

As a seasoned contractor once told a less experienced assistant, “There are only three things I worry about when evaluating a new jobsite. Those three things are drainage, drainage and drainage!” There is a lot of wisdom in those words. A solid drainage plan is essential whenever any land disturbing activities take place.

When considering drainage, the most obvious application involves moving surface water away from the construction site. The water is typically moved by either sheet flow over a vegetated surface or by concentrated flow via a drainage channel or swale. Water can also be collected by drainage manholes and moved away from the site by piping systems.

When considering drainage, the most obvious application involves moving surface water away from the construction site. The water is typically moved by either sheet flow over a vegetated surface or by concentrated flow via a drainage channel or swale. Water can also be collected by drainage manholes and moved away from the site by piping systems.

Water concentrated below the surface presents a special challenge. When subsurface waters have no means of movement off site, soil saturation can occur. Such undrained areas can cause problems with soil stability, maintenance and effective use. This explains why virtually all athletic fields, golf courses and other heavily used turf surfaces have drainage systems built in below the soil surface.

Henry French, a lawyer from Concord, Massachusetts, invented a system to move subsurface water in 1859. His basic concept is still lives, and is known to this day as the French Drain system. Mr. French used a combination of roof tiles and gravel to form this early solution. The idea was to collect water below the soil surface and move it to daylight away from the site.

Henry’s fundamental concept remains in use, although the development of perforated pipe and geotextile fabrics have refined the composition of French Drains. Today such systems consist of a perforated pipe surrounded by crushed stone, with the whole system enveloped by a non-woven geotextile fabric.

Henry’s fundamental concept remains in use, although the development of perforated pipe and geotextile fabrics have refined the composition of French Drains. Today such systems consist of a perforated pipe surrounded by crushed stone, with the whole system enveloped by a non-woven geotextile fabric.

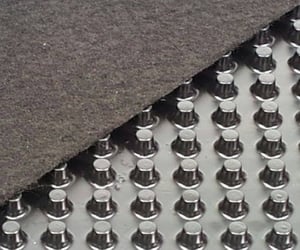

In recent years the subsurface drainage industry has evolved rapidly, and today drainage composite systems have brought about fundamental change. In short, drainage composites provide an alternative to conventional French Drains that cost significantly less to install but perform at much higher levels. Typical drainage composites consist of a molded three-dimensional plastic core surrounded by non-woven geotextile fabric.

Drainage composites collect water over about 85% of the product surface. The perforated pipe at the core of the French Drain system can only collect water through the small perforations at the bottom of the pipe, or about 5% of the pipe’s exterior. Significant performance advantages for drainage composites, added to much lower installation costs, result in total installed costs approximately 50% lower than conventional French Drain systems.

French Drains require a wide trench to install pipe and crushed stone enveloped in geotextile fabric. Drainage composites provide a one component system, with no stone required. The products can be installed in a very narrow trench and then embedded in washed concrete sand. The sand forms a filter layer to help prevent soil fines from clogging the geotextile surface of the drainage composite.

French Drains require a wide trench to install pipe and crushed stone enveloped in geotextile fabric. Drainage composites provide a one component system, with no stone required. The products can be installed in a very narrow trench and then embedded in washed concrete sand. The sand forms a filter layer to help prevent soil fines from clogging the geotextile surface of the drainage composite.

Team EJP manufactures its own drainage composite product line, EJP-DRain™. Drainage composites are available for many used beyond the landscape and athletic field market. Similar products are used for green roof and foundation drainage, behind retaining walls, along the face of bridge abutments, and in countless other applications.

In simple terms drainage composites perform at a high level while costing much less than conventional solutions. These factors combine to form a very strong value proposition for owners, landscape architects, civil engineers and contractors.

Team EJP started producing its first drainage composite product group in 2007, and the results have been dramatic. When the City of Middletown, New York rebuilt invested $11 million to rebuild its athletic complex in 2008, Team EJP provided the subsurface drainage composite system.

More recently, an athletic complex in Augusta, Maine approached Team EJP for help on a drainage problem. The complex had been built without a drainage system, and wet fields had resulted in the cancellation of many scheduled events. Team EJP representatives visited the site and recommended and EJP-DRain™ installation. Budget limitations resulted in installation of only half the field area in the fall.

More recently, an athletic complex in Augusta, Maine approached Team EJP for help on a drainage problem. The complex had been built without a drainage system, and wet fields had resulted in the cancellation of many scheduled events. Team EJP representatives visited the site and recommended and EJP-DRain™ installation. Budget limitations resulted in installation of only half the field area in the fall.

For the owners of the Augusta complex, seeing was believing. The following spring the owners returned to the site to evaluate the results, and liked what they saw. The remaining half of the field received the same treatment that same year.

Drainage composites can even be used under traffic bearing surfaces. Drainage is a critical component in roadway construction. John MacAdam (1756-1836) in considered the father of modern road building, and he was famously quoted as saying, “If it does not drain it will not be a road, at least not for very long.”

Team EJP represents a highway grade drainage composite product line known as RoaDrain™. The product was specified and used on a project on Route 1-A in Winterport, Maine. A particular section of that roadway had been constructed over very wet and poorly drained soils. As a result, the road surface was constantly breaking up and failing. The RoaDrain™ installation relieved the drainage pressure and provided a long term solution to the ongoing problem.

Team EJP represents a highway grade drainage composite product line known as RoaDrain™. The product was specified and used on a project on Route 1-A in Winterport, Maine. A particular section of that roadway had been constructed over very wet and poorly drained soils. As a result, the road surface was constantly breaking up and failing. The RoaDrain™ installation relieved the drainage pressure and provided a long term solution to the ongoing problem.

Team EJP has eight decades of experience in the business of water. Our professional sales representatives stand ready to help solve our clients’ toughest drainage problems. Contact Team EJP today!