Effluent Pump Basics: What You Need to Know

- Home

- Team EJP Blog

- Effluent Pump Basics: What You Need to Know

- Mar 26, 2020 8:50:32 AM

- Everett J. Prescott

When you're trying to move water, there are a number of options available, but water in your sewer system requires special handling. Because of the potential solids, bacterial load and similar concerns, when you need to get your greywater from point A to point B, you need an effluent pump, which is used to move water with limited solids. Here's a quick breakdown of what you should know to get started with effluent pumps and how to keep your pumps operating effectively through proper management.

What Kind of Pump?

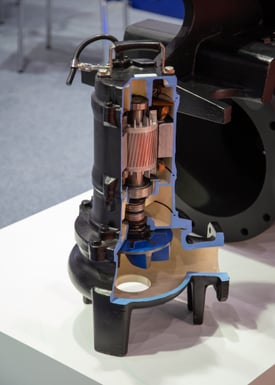

To start, let's consider some different features on the pump you're thinking about buying. When it comes to housing, cast iron tends to be more expensive, but also more durable and heavier, while thermoplastic is less expensive and stands up well to corrosion, but often doesn't last as long. For sizing your pump, pay attention to both the horsepower as well as the gallons per hour it can handle. An effluent pump is designed to handle limited solids of 1/2" in diameter or less and is used when water must be moved up a grade into a drain.

- High Head Effluent: When you need to pump effluent to a significant height, a high head effluent pump is the way to go. It can handle

much higher elevations, but will also take more power to move the water to that height.

much higher elevations, but will also take more power to move the water to that height. - Sump Effluent: A sump effluent is essentially a sump pump that can handle moving some limited solids a short elevation to a drain field or similar structure. It draws less power, but won't move the water as high.

Tips for Effective Pump Management

- Start with a pressure reading. As soon as your new pump is installed, take a pressure reading as a baseline for your system for future troubleshooting.

- Save your pump data by hanging onto the second sticker that's included in the box or by snapping a quick picture of it with your smartphone, which also documents the date of installation for warranty issues.

- Make sure the warranty process for your selected pump is easy. You don't want to spend weeks with your pump out of commission waiting on warranty paperwork to process.

- Check bushings and bearings to ensure you've purchased a good-quality pump. The bearings should spin freely and the bushings

remain flexible.

remain flexible. - Don't skimp on your pump - only buy professional grade. Most big-box stores only carry consumer-quality pumps, which will not last nearly as long.

- Understand how your pump works. By having a basic understanding of your pump function, you'll be able to more quickly diagnose problems and effect repairs.

- Be careful of what goes down the drain. Plumbers make hundreds of thousands of dollars every year clearing items out of the drain that don't belong.

- Make sure you know how to turn the pump on manually. This makes it much easier to determine whether it's a pump or a control problem during a crisis.

By taking the time to have a solid understanding of how effluent pumps work, what type you need and how to manage it for effective use, you can keep your pumps operating efficiently for many years. If you need help to determine the right kind of effluent pump for your water utility's needs, the experienced professionals at Team EJP are ready to help. Please feel free to contact us today with any questions, for additional information or to get a quote on our line of high-quality effluent pumps.