What Type of Pipe to use for Corrosive Liquids and Sewer Applications?

- Home

- Team EJP Blog

- What Type of Pipe to use for Corrosive Liquids and Sewer Applications?

- Sep 28, 2015 1:00:29 PM

- Everett J. Prescott

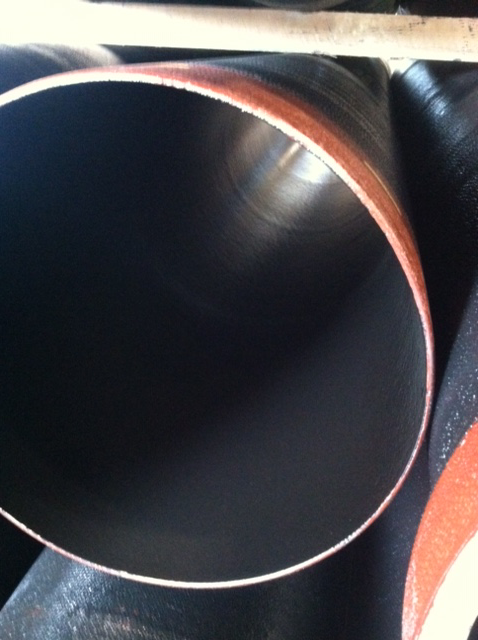

When you're dealing with corrosive liquids in supply lines and sewer drainage applications, it can be really hard finding a pipe solution that delivers the performance you need without compromising the safety and durability you need for your unique situation. What kind of pipe material works best for moving these potentially dangerous liquids that won't quickly corrode and fail? One of the best options we've found in the industry are epoxy lined ductile iron pipe. Here's why:

What is Epoxy Lined Ductile Iron Pipe?

Though cast iron pipe is still commonly found in our industry, ductile iron pipe is quickly becoming the go-to solution for industry and municipalities. Why? Ductile iron incorporates nodular graphite to improve resistance to impact and fatigue, making it much less susceptible to the brittleness that plagues traditional cast iron installations. As an extension of this durability, an epoxy lining helps reduce corrosion issues within the pipe, providing a longer life span and much lower chance of failure due to corrosion.

How Epoxy Lined Ductile Iron Pipe Provides Serious Performance Against Corrosion

But what about when you're dealing with corrosive liquids? Because the epoxy lining provides the best possible protection against corrosion, it resists the possible corrosive action such liquids often deliver to an otherwise unprotected ductile iron pipe system, ensuring years of reliable service in difficult sewer pipe situations. It's been used through thousands of sanitary sewers and has exceeded expectations in lab tests and on the job performance for many years, especially compared to standard cast iron pipe or even unlined ductile iron pipe.

But what about when you're dealing with corrosive liquids? Because the epoxy lining provides the best possible protection against corrosion, it resists the possible corrosive action such liquids often deliver to an otherwise unprotected ductile iron pipe system, ensuring years of reliable service in difficult sewer pipe situations. It's been used through thousands of sanitary sewers and has exceeded expectations in lab tests and on the job performance for many years, especially compared to standard cast iron pipe or even unlined ductile iron pipe.

How Long Has Epoxy Lined Ductile Iron Pipe Been in Service?

Epoxy lined ductile iron pipe was developed in the late 1970's and has been in service around the world with thousands of miles of durable, reliable piping in place since the early 1980s. There has yet to be even a single instance of lining failure over the thirty plus years its been in service. It was designed to reach the best of both worlds by providing cement mortar lining's reliability without the extra weight. The specialized novalec epoxy has delivered similar superior protection over several decades, providing unparalleled performance when compared to other pipe lining solutions.

What Are Some Precautions You Need to Take When Implementing Epoxy Lined Ductile Iron Pipe?

Though epoxy lined ductile iron pipe provides a much more reliable and durable sewer line solution, there are a few situations where you should take care. Though the epoxy is resistant to most situations, chemical injections that provide odor control can cause damage to the pipes, gaskets or protective linings. These treatments should only be undertaken with extreme caution after you've first tested the chemical against a sample piece of pipe, to ensure the best possible outcome from your treatment. To ensure you're getting the right results, it's recommended that you consult with a sales professional to receive recommendations tailored to your individual situation without the risk of premature failure.

Ductile iron pipe that has an epoxy lining should only be pushed when a restrained joint system won't allow the bell shoulder and the spigot to contact each other, and should never be attempted if your system incorporates restraining gaskets. It can, however, be pulled with either restrained joint pipe or restraining gaskets . You shouldn't hone the pipe clear to the bell shoulder no matter if there is or is not restraining gaskets in place. These precautions help ensure you don't damage the lining.

If you're ready to improve your system's lines, epoxy lined ductile iron pipe is a great option to explore. For more information, please contact the professionals at a Team EJP today.

Protecto 401 Product Guide!

A free indepth product guide for Protecto Product Guide. Get Information like:

- Standard Specifications

- Comparison Testing

- Flow Charts

Download Now