Protecting Your Pipes With Corrosion-Resistant Exterior Coatings

- Home

- Team EJP Blog

- Protecting Your Pipes With Corrosion-Resistant Exterior Coatings

- Sep 25, 2015 1:05:10 PM

- Everett J. Prescott

When you're dealing with corrosive soils, how can you ensure that your ductile iron pipe is protected from corrosion and premature failure points? Like any type of naturally-occurring aspect of the environment, soils vary greatly and can be very corrosive, causing problems with your pipe systems if proper precautions are not made. But how can you decide what needs to be done? Here is some additional information on corrosive soils, how to mitigate the corrosiveness of the soil and what type of pipe coating works best to reduce the problem.

What Are Corrosive Soils?

When it comes to plants and animals, soil corrosiveness is simply something that they adapt to, like any other form of evolution. However, man-made structures such as sewer drain systems don't have the ability to evolve to meet that need. To avoid the financial cost and failure points caused by corrosive soils, mitigation must take place in the process of designing, constructing and maintaining the system. When the process of preparing an installation occurs, changes in the soil can drastically change the soil's condition.

How Can They Be Mitigated?

There are a wide range of conditions caused when working with soil that can cause it to become more or less corrosive. Aeration, which involves the ability of air to move through the soil, affects water retention and evaporation, but soils that have been well aerated provide lower corrosion levels as water is able to be moved out of the soil and into the air. Soil type plays a large role in this issue, as sandy soils provide the best possible drainage and clay soils the worst. Well-aerated soils tend to be have red, yellow or brown tones while poorly aerated soils tend to be grey in appearance. Low soil pH is another indicator that leads to corrosion, with more acidic soils with a pH that's under 5 leading to serious corrosion. The pH level can also change during times of high rainfall or drought. This is because the moisture content of the soil can drastically affect corrosion. Damp soils provide the needed component, water, for the corrosion process to begin. Temperature also plays a part, with temperatures approaching 32° F increasing resistance to corrosion that begins rapidly increasing after freezing has been reached and the temperature continues declining. Sulfate and salt levels also more susceptible to corrosion.

There are a wide range of conditions caused when working with soil that can cause it to become more or less corrosive. Aeration, which involves the ability of air to move through the soil, affects water retention and evaporation, but soils that have been well aerated provide lower corrosion levels as water is able to be moved out of the soil and into the air. Soil type plays a large role in this issue, as sandy soils provide the best possible drainage and clay soils the worst. Well-aerated soils tend to be have red, yellow or brown tones while poorly aerated soils tend to be grey in appearance. Low soil pH is another indicator that leads to corrosion, with more acidic soils with a pH that's under 5 leading to serious corrosion. The pH level can also change during times of high rainfall or drought. This is because the moisture content of the soil can drastically affect corrosion. Damp soils provide the needed component, water, for the corrosion process to begin. Temperature also plays a part, with temperatures approaching 32° F increasing resistance to corrosion that begins rapidly increasing after freezing has been reached and the temperature continues declining. Sulfate and salt levels also more susceptible to corrosion.

What Kind of Pipe Coatings Are the Most Effective against Corrosive Soils?

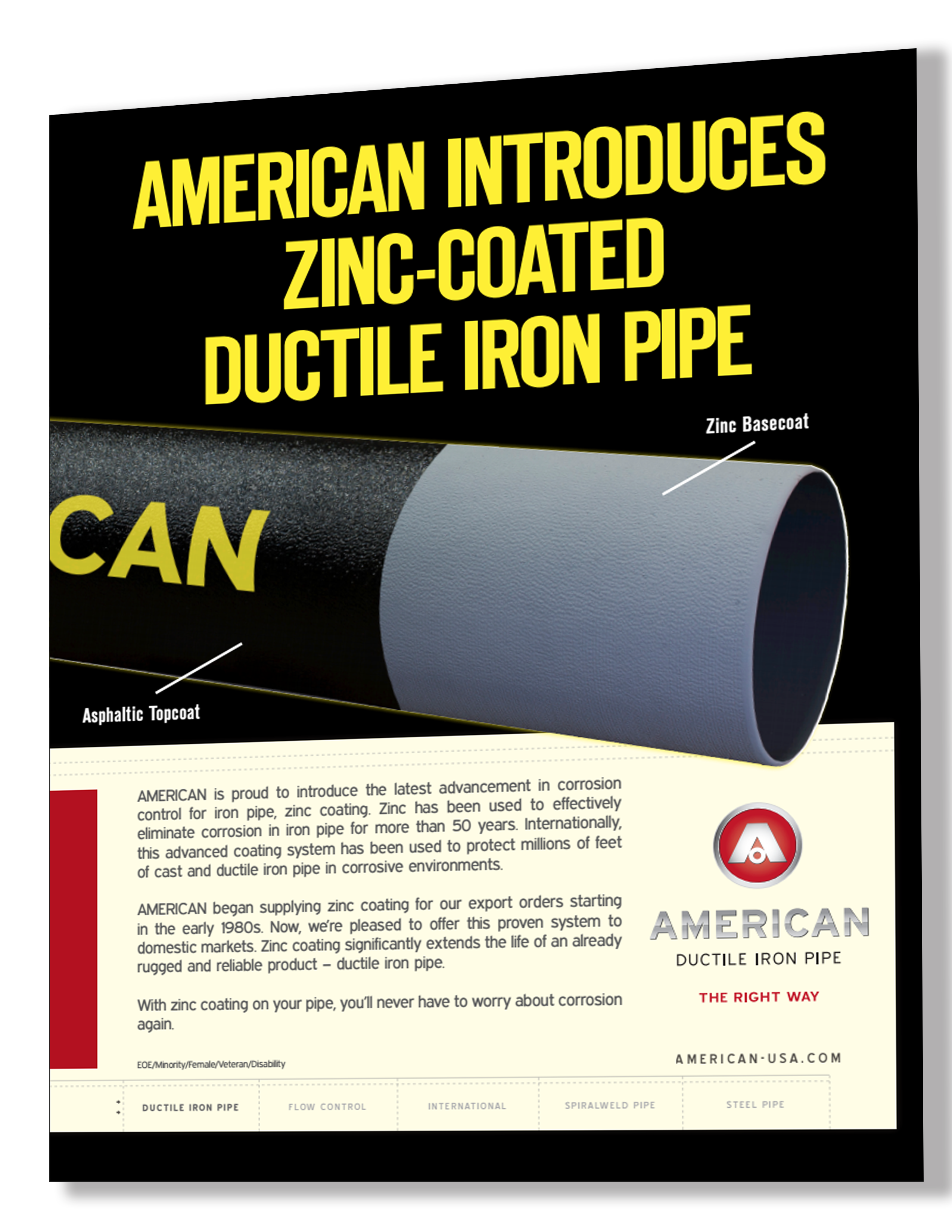

If you have no choice but to deal with a corrosive soil because maintenance cannot be maintained to keep it dry and well aerated, pipe coatings are another option to consider that helps keep your pipes protected. One of the most common methods is placing a zinc coating on the pipe's exterior. Used for over 50 years to good effect, It provides great protection at a sufficiently economic price point to make it attainable by most public utilities or factory settings. It is reactive enough to act as a cathode in the soil without completely disintegrating and leaving your pipes open to corrosion damage. Compared to the original coating of 130 grams per square meter, the change in the early 1980s to 200 grams per square meter ensures optimal performance in corrosive soils.

If you're considering installing iron pipe into corrosive soils, following these guidelines are an effective way to protect your investment and ensure years of reliable service. If you still have questions or need additional information to make a decision, please contact Team EJP today for more details. We're always happy to help you find the perfect solution to your plumbing problems.