Install Hydrants & Valves Fast With ALPHA Technology

- Home

- Team EJP Blog

- Install Hydrants & Valves Fast With ALPHA Technology

- Sep 15, 2020 10:45:00 AM

- Everett J. Prescott

*updated 08/21/2020*

Updating your hydrants and valves can dangerous and time-consuming. Your crew is at risk, with worksite accidents being the nightmare of your water utility, impacting your crew's morale, increasing your worker's comp insurance, slowing don work and potentially increasing your liability. Having your water system down for extended periods of time while replacing hydrants leaves your area open to fire damage as firefighters are forced to rely on tanker trucks.

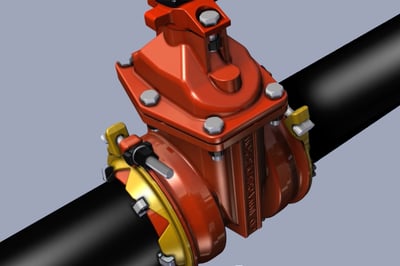

But, what if there was a way to get the job done more safely and in a more efficient manner? What if installation could be completed in a matter of minutes rather than hours? The resilient wedge NRS gate valve with ALPHA ends give you that advantage. The preassembled, easier to install system provides better accessibility, significantly reducing installation time and risk to your workers and your region's structures. Here's more about how this dynamic water utility technology improves worksite safety and speeds up the job.

Watch how easy installation is!

The Alpha resilient wedge gate valve is a great option to consider for your hydrant on 4" to 12" water lines. You can order them preassembled with your hydrants, saving you time right out of the box. It's much easier to install, requiring only one strong 304 stainless steel bolts to be tightened as compared to 12 to 16 on most other attachment systems. The bolts are located at the top, making them more accessible to workers. This means you don't have to elevate the valve to connect the bottom bolts as you would on a mechanical joint or do additional excavation to reach everything you need. The pressure-activated gasket on the Alpha valve allows your crew to use less pressure to install the valve, only 45 lb-ft of torque.

The significantly reduced time your crew spends installing the Alpha valve means they're more productive and that water service is restored to your customers much more quickly. But how much time does it save? The entire fitting can be installed in four minutes or less by a single worker as compared to half an hour to an hour by multiple crew members, saving you about 30-45 minutes per installation. This allows your crew to get onto the next item on their task list that much faster.

The significantly reduced time your crew spends installing the Alpha valve means they're more productive and that water service is restored to your customers much more quickly. But how much time does it save? The entire fitting can be installed in four minutes or less by a single worker as compared to half an hour to an hour by multiple crew members, saving you about 30-45 minutes per installation. This allows your crew to get onto the next item on their task list that much faster.

By using simple stab-fitting technique, the 304L stainless steel grab hooks grabs the outside of the pipe, and the higher the pressure, the more tightly the pipe pushes against the seal. This means less torque is needed to create a tight seal. The ductile iron grippers work well with pipes that are out of round as well as an angular deflection of up to four degrees, making it a more forgiving fixture to use in the field. Altogether, this creates an assembly that significantly reduces installation time, allowing a single worker to spend less time in the trench while still getting the job done with a high-quality fitting rather than a pair of workers holding the fitting and tightening bolt after bolt.

The Alpha restraint system works with a wide range of pipe types, including;

- Ductile Iron

- Cast Iron Classes A, B, C and D,

- PVC ISP Schedules 40, 80 and 21,

- PVC C900 and C909,

- HDPE SDR 9, 11, 13.5 and 17 without pipe stiffeners

HDPE SDRs above 17 do require pipe stiffeners, but can still be easily used with the Alpha restraint system. It's constructed from strong ductile iron, allowing it to withstand pressures of up to 250 PSI. Because Alpha's products are created domestically, you're supporting American industry and keeping Americans at work creating innovative quality products.

By significantly reducing installation time, the ALPHA technology accessibility makes it easier to install, even in dangerous circumstances. This keeps your crew moving through their task list and out of harm's way. If you're ready to see what this valve can offer your water utility, Team EJP is ready to help. Please feel free to contact us today with any questions or click below for more information.